I installed a DRO on the Clausing. I got Aikron scales and console - the LCD console, a 1 micron slim magnetic scale for the cross slide, and 5 micron standard width scale for the carriage. So far I'm very happy with it - the user interface is better than some US-made, much more expensive DRO's I've used, and being able to store a library of tool offsets is a real game changer - all the lathes I've used until now have been communal (and thoroughly abused...), so even though some of them had DRO's none of them had proper tool libraries. Tool libraries make turning so much more efficient, and for tolerances over 50um or so I don't even need to measure anything.

Checking that the scale aligns with the cross slide travel - I did the vertical alignment by loosely tightening the mounting fasteners at each end and just tapping the the scale into alignment:

Thanks to the match-machining I did on the cross slide cover, I didn't have to do any shimming to get the z-alignment of the scale right:

Scale and read head both mounted:

I made a scale cover by gluing a neoprene rubber sheet to the cross slide with some Loctite 380. Eventually I want to make a proper guard for the scale and proper way covers, but this does the job for now:

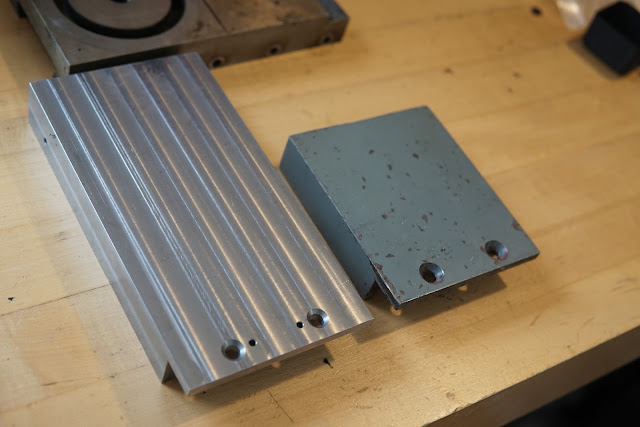

Mocking up the position of the carriage scale and read head on the back side of the machine:

To get the scale parallel to the lathe bed vertically, I sandwiched some bearings between a ground surface on the underside of the bed and the top of the scale:

Double checking the alignment with an indicator after mounting, but no adjustment required on this axis. It took a few shims between the bed casting and scale in the other direction:

Living room getting nicer with each day ;). Looking good!

ReplyDeleteThat bearing trick is pretty neat; never thought to use one as a gauge before... Are you considering modifying the spindle for speed/SFM control as well, or just going to keep it crunchy with the gears?

ReplyDeleteThe bearings aren't very stiff in that direction, but as long as you don't squeeze too hard it works

DeleteIt's definitely going to get a real motor at some point. Currently it's a 3/4HP AC motor with stepped v-belt pulleys for changing speed. The v-belts spin a countershaft with a timing pulley to the spindle, and it'd be really easy to just drive the timing pulley straight from a motor.

That's a great set-up. I have the exact lathe and recently bought an Aikron 2 axis lathe kit. I went with glass scales. The long Z axis scale will be no issue but the X axis scale is too thick to fit under the tool post. I thought about ordering a narrow glass scale or even the magnetic scale but don't know if you can mix styles and still use the same console. Anyone know if this can be done? I contacted Aikron through their website but they are away for Chinese New Year.

ReplyDelete