Here's the rest of the build log:

The change that got them from sounding terrible to sounding tolerable was reducing the tension in the membrane as much as possible. The first few test versions were intentionally tensioned, which turned out to be a bad idea, causing weird notches and resonances in the frequency response. The new membrane is glued to a frame under no tension. I also switched to an even thinner flex pcb material, Pyralux AC 091200EV, which has a 12 micron kapton layer, 9 micron copper layer, and no adhesive.

After the toner transfer. Getting the toner transfer right without wrinkling the material was tricky:

This time I glued the membrane to a fiberglass frame. To get the PCB flat without tension, I stuck it down to a metal plate by wetting the plate. I forgot to take a picture of these assemblies, but here's one of the original PCBWay flex pcbs glue to an identical frame:

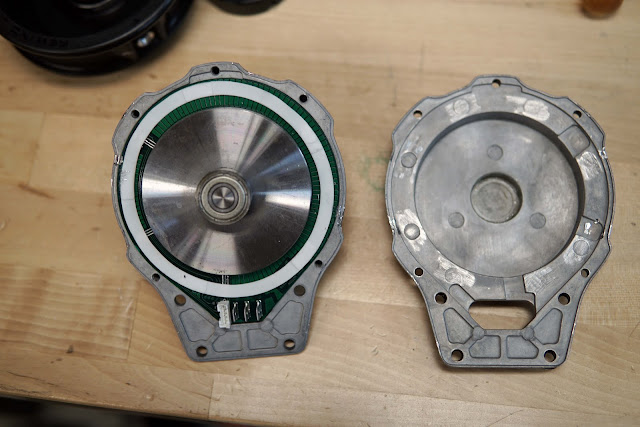

For the final headphones I'm using a single sided magnet array - I first built a single driver, and did experimenting with both single and double arrays, and qualitatively could not hear any significant difference between the two. And a single array is about half the effort of the double array. Here's the test-driver, with a plastic back, and the first ultra-thin board I was able to successfully etch:

I machined two new aluminum backs, and stole the headband from a cheap pair of headphones. Maybe eventually I'll get around to making a nice headband, but for the time being I'm not particularly interested in building headbands:

On a dummy head:

They sound decent. They're a bit bass-heavy, and require some equalizing, but once that's done I quite like them.