Here's the weed-wacker. I just got the head of the tool- they make a base called the "drive unit", which holds the battery and electronics. Each head has its own motor:

The motor's right at the end, direct driving the spool of wire:

Removed from the stick. Three board-mount faston terminals for phase power, and another connector for hall sensors.

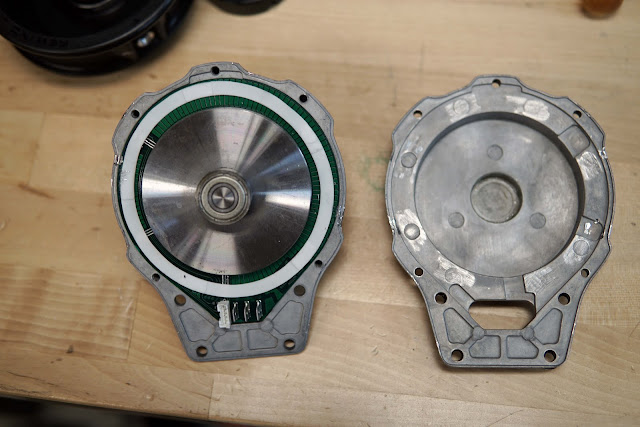

The motor was a huge pain to take apart, as it is pretty much entirely held together with retaining compound. With a hammer and some screwdrivers I was able to pull off the back cover:

The shaft and front bearing were pushed out of the other half of the housing with a gear puller. There's a ring of thermal pad on one side of the board:

It's a dual-rotor design, with the PCB stator sandwiched between the two halves of the rotor. The rotor is held together by even more retaining compound:

To pull off half of the rotor, I gripped it in a small lathe chuck and used a gear puller to pull it off the shaft:

First a closer look at the stator. The board had at least 4 layers, and probably has 4 oz copper - it's very dense feeling.

Some observations and thoughts:

- Each phase has 4 4-turn coils, and the 3 phases are overlapped. This is a full-pitch winding.

- This winding pattern results in a large area of end-turn, so the actual "active" area of the stator is unfortunately small - less than half the area of the PCB actually produces torque.

- The traces neck down and become thinner within the active area. Presumably this is to reduce eddy current losses from the magnets swinging over the traces.

- The hall sensors are through-hole halls, surface mounted sideways into cutouts in the PCB, so they add almost no additional thickness.

- The empty space around the edges of the board are filled with radial strips of copper. I'm not really sure why. Maybe for thermal reasons? The edge of the board is heatsinked to the aluminum housing through a ring of thermal pad.

Here's the patent for reference.

The two rotors have single-piece magnets magnetized with 4 pole-pairs:

One of the reasons it's all held together with retaining compound is that the bearing bores in the castings aren't even post-machined. The bearing is just glued straight into the rough, tapered hole in the casting:

Back-EMF is pretty sinusoidal. An FFT reveals a little bit of 5th harmonic. Flux linkage is ~.0044, for a torque constant of .0264 N-m/A (peak phase amps). Line-to-line resistance is 125 mOhms. This gives a motor constant of .086 N-m/sqrt(watt).

Over all it's not a particularly high performance motor for it's size or weight. There's a lot of dead space, and a very heavy, high-inertia rotor.

Can I get your email? I have read your paper about cheep actuator of cheetah. I want to ask you some questions. Hope you can answer. Thank you very much!

ReplyDeleteThere's a contact form here:

Deletehttp://build-its.blogspot.com/p/about.html

Sorry I have tried many times to press the "send" button, but there is no response. I wonder if you have received my e-mail. My e-mail address is 940525739@qq.com, if you don't mind you can directly send to me. :)

DeleteThis comment has been removed by the author.

DeleteSo what's become of this company and their CORE electric motors? Troy-Bilt has a few CORE-tech outdoor power tools, but they seems to be discontinuing them, as you can't order them anymore. In fact I have their mower and weed-trimmer and they are fabulously awesome. I want more, though. Can't find anything about them, now.

ReplyDeleteOh yea! I thought so too, amazingly fabulously awesomeest motors I've ever seen!

Delete"Over all it's not a particularly high performance motor for it's size or weight. There's a lot of dead space, and a very heavy, high-inertia rotor."

ReplyDeleteI have tested this motor myself, and I strongly disagree with your results, although I found them very very interesting. The motor uses around 500 watts, and produces over a horsepower(around 1000 watts of power), 6800 RPM @ around 1 ft/lb of torque.

There could be some room for improvement within the motor itself, however. Perhaps a re-design and optimization. I believe you may have come to your conclusion from examining the diagnostics, but the real-world performance blows other electric motor designs totally out of the water. I can do things with the(40v version, Elite) that I cannot do with a 2-stroke gas trimmer. Perhaps it is the higher RPM that this motor type develops, as you said it is a very heavy, high-inertia rotor.

I believe there is tremendous potential for this motor design, given design improvements.

?

Delete1000 watts output at 500 watts input violates conservation of energy...

A 1 kW RC car motor, for example, is much smaller and lighter.

Its the RPM that it develops, the inertia(6800 rpm) with a heavy rotor. It uses 500 watts and puts out over a horse. Only problem is not a whole lot of start up torque. The key is higher RPM.

DeleteOh and thank you for responding so quickly! I would love to discuss with you the results! :) You are an amazing person!

DeleteHi again! I have just a few questions if you don't mind, I am extremely interested in your results, but I don't really understand some of the variables(I am a software programmer, just getting into hardware, especially drones).

DeleteQuestion 1: "There's a lot of dead space".

So from my limited autopsy of the motor, I believe there are 3 phases, so how many degrees are not used? I assumed, as with most 3 phase motors, there are 120 degrees that are used in a single phase, so the other 2/3 of the motor is unused. I also assumed that there are multiple layers, from looking at the patent, and that the phase goes all the way through the layers. I made a color diagram of the path of electricity through the coils in a phase. What did you mean by dead space exactly?

"Back-EMF is pretty sinusoidal. An FFT reveals a little bit of 5th harmonic. Flux linkage is ~.0044, for a torque constant of .0264 N-m/A (peak phase amps). Line-to-line resistance is 125 mOhms. This gives a motor constant of .086 N-m/sqrt(watt)."

1. "Back-EMF is pretty sinusoidal" What does that mean? Sorry, I'm new to hardware and motors, but I'm learning quickly!

2. FFT?

3. 5th harmonic?

4. So from your results(.0264 N-m/A), how many real world Newton Meters of torque could this motor produce?(Or am I interpreting that wrongly, perhaps that is dealing with something else)

5. ".086 N-m/sqrt(watt)" so .086 N-m/sqrt(500) = .086 N-m/22.36 = 0.0038 N-m? Oh I probably messed that one up.

I appreciate it, just trying to understand, this is very exciting! Most in depth explanation ever!

Oh, and the design too, Axial Flux is an amazing next-gen design. Good for some things, WAY better than Radial Flux, even though RF has more start up torque. AF is WAY more efficient, you don't need the heavy iron core, the CORE design (mostly) eliminates Eddy Currents(so I've heard), or does it? I would LOVE to discuss this! You are the only person I've seen that analyzed the CORE motor this deeply.

ReplyDeleteOk, here is that picture of the path the electricity takes through the conductor down to multiple layers.

ReplyDeletehttps://oi1174.photobucket.com/albums/r605/LordNelson7/CoreMotorElectricalPath_zpsr1lz76qj.png?t=1559509385

The electricity starts in 53B(A+) and ends in 53A(A-). There are only 3 prongs in a real-world motor(there are 6 prongs in the diagram), so I am assuming the next phases prong is used as the end.

Starting on PCB pattern 32(the layer on the left), which is the top layer, the electricity flows in A+, through the conductor(colored brown). The first part of the conductor is thick, then flows through a thinner wire-type area, then to the middle, a slightly thicker area, then to the thin again, then out the "lime green" colored circular area, down to PCB Pattern 33, the second layer, our of the "lime green" colored circular area, on to the light brown thick area, around to a thin layer, onto the middle, onto "bright red" color, then "dark blue" color, then "deep purple", then "dark green", then into "yellow" circle, back to PCB pattern 32, layer 1, at yellow circle, along thick "dark green", to thin, to middle, to "pink" circle, down to layer 2, to dark green, deep purple, dark blue, bright red, light brown, to blue circle, up to layer 1, along "dark yellow" back to A-.

Core sold-out to a giant in the lawn care industry who wanted to turn-key into the growing "environmentally-friendly" commercial landscaping market. We built that PCB (and many more like it) but take no credit for the design (we build-to-print).

ReplyDelete